Conveyor systems

Find ideas

Based on your ideas and key figures, we work with you to develop innovative concepts and solutions.

After an intensive analysis of your needs and requirements, we create initial sketches and drafts to implement your ideas in the best possible way.

We attach particular importance to creative ideas that are both functional and aesthetically pleasing.

Our aim is to develop customized solutions that are precisely tailored to your individual requirements.

Through close collaboration and regular feedback loops, we ensure that the end product meets your expectations and supports your long-term success.

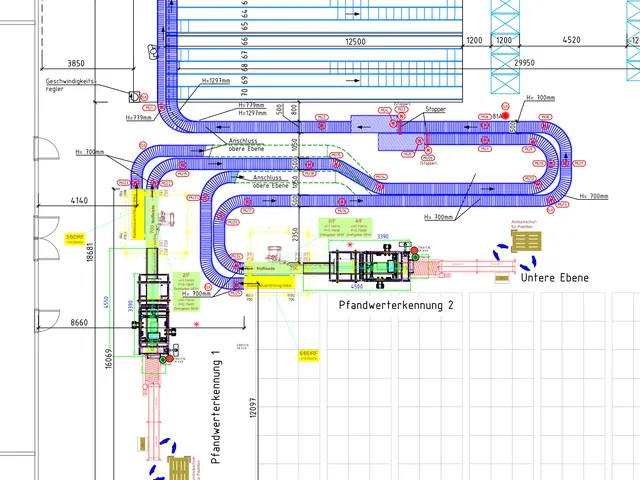

Designing and calculating

The conveyor system is now drawn in detail in all its complexity, calculated and reliable suppliers are contacted in order to obtain the best possible materials and components for the project.

The plan is implemented down to the smallest detail to ensure that all aspects of the container conveyor technology are perfectly coordinated and smooth operation is guaranteed.

All possible risks and challenges are taken into account to ensure that the project can be completed on time and within budget.

Implement

We take on the responsibility of accompanying the project together with you and the suppliers from start to finish.

We ensure that the performance of the system is checked and that the quality of execution meets the highest standards.

We will also be happy to visit you some time after commissioning to inspect ongoing operations and discuss any potential improvements.

Our aim is to ensure that you are completely satisfied for many years to come and that the material flow runs smoothly and efficiently.

Empties plant project

Challenge:

- Conception and delivery within a very short time, hundreds of meters FT

- Use of existing components

- Toughest environmental conditions

Implementation:

- Simulated creation of the layout during assembly (3 months from order to IBN)

- Control and switch cabinet construction in the shortest possible time

- Cooperation with Knapp Fördertechnik (empties detection)

Result:

- System was handed over in working order, within the specified time frame and budget

Production linking project

Challenge:

- Linking production through to goods issue

- Heavy weights

- Slim design

Implementation:

- Planning the flow of goods

- Layout and tendering

- Assembly and IBN

Result:

- System was realized within the specified time frame and budget

Production traffic circle project

Challenge:

- Production feed in confined spaces High load on conveyor technology

- Even the smallest products can be conveyed

- To be realized during ongoing operation

Implementation:

Layout in close coordination with customers

Assembly and IBN

Result:

System was realized within the specified time frame and budget